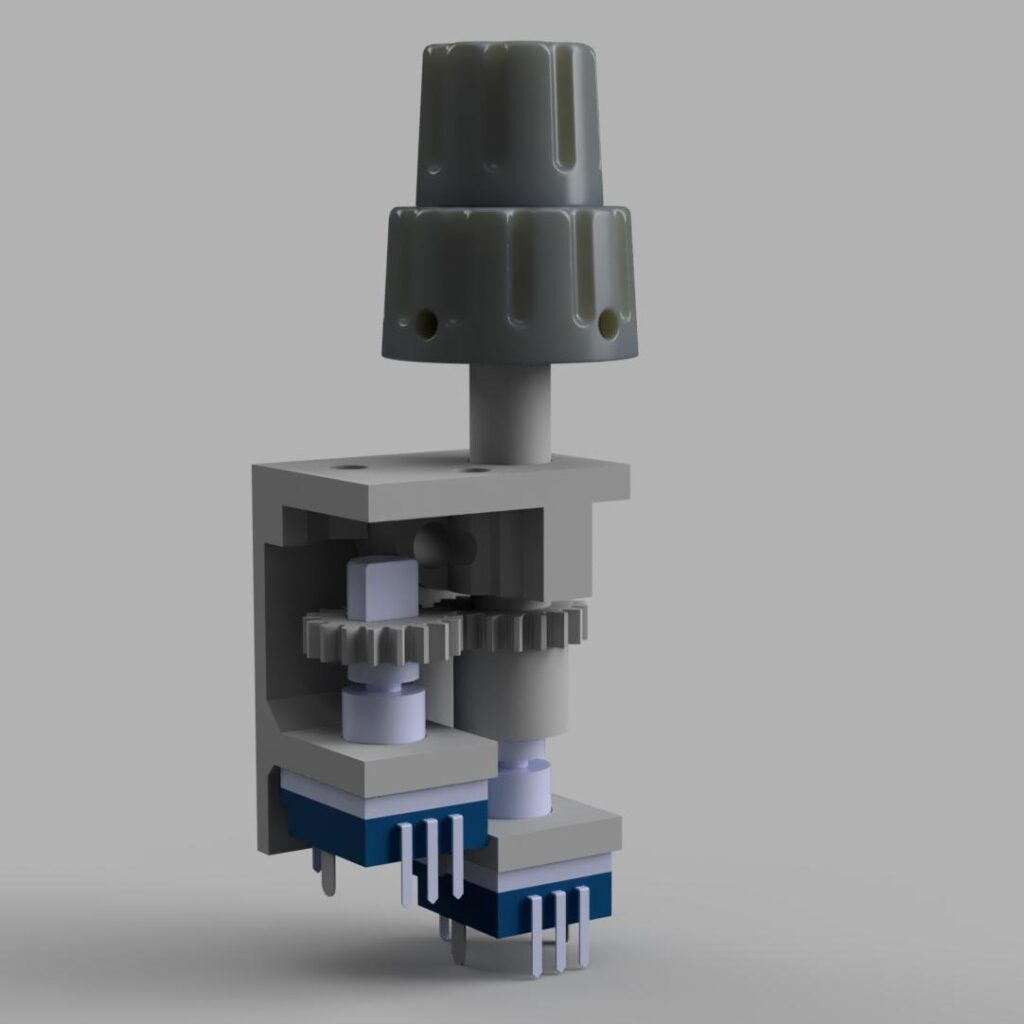

After all the design improvements during the build process of the MIP it was time to with a more precise construction. This design can used in exchange for the current dual rotary encoders of the pedestal.

There is no more need to glue acrylic parts together and deal with the measurements the industrial made parts come with. All nedes parts are 3D printed and the case can be disassembled without destroying the axis. Also the guide wholes for the shafts are longer so that is less wiggling at the end.

An additional M3 x 5,7 mm heat insert is used to screw the two parts of the case.